Cleanrooms and Cleanroom Equipment

Perotech presents some of the largest companies that manufacture cleanrooms and cleanroom equipment in the world. We sell everything from individual HEPA Filter Fan Modules to full turnkey aerospace cleanrooms. We have a full range of accessories from Air Showers to Pass Throughs and can help you with any special purpose room imaginable.

Call QC for pricing and quotes: 647 268-6306 Email: qc@perotech.com

BioSafe® All-Steel Biopharmaceutical Modular Cleanrooms

Why Choose BioSafe® Modular Cleanrooms?

All-steel construction ensures strength, durability, and long-term value

GMP- and ISO-compliant for biopharma, research, and medical device facilities

Quick installation with modular, pre-engineered components

Customizable configurations to meet any process or spatial requirement

Easy to clean and maintain, supporting aseptic operations and contamination control

Flexible design allows future expansion without downtime

Precision-Engineered. Ultra-Clean. Built for the Future of Biopharma.

Transform any environment into a state-of-the-art, particle-free cleanroom with BioSafe® All-Steel Modular Cleanroom Systems. Designed specifically for biopharmaceutical and life science applications, BioSafe® cleanrooms deliver superior durability, seamless cleanability, and total flexibility for your facility layout.

Our modular, pre-engineered cleanroom panels provide a fast, cost-effective, and compliant way to create controlled environments that meet the highest standards in GMP, ISO, and FDA-regulated industries.

Built with Strength and Cleanability in Mind

The BioSafe® Panel System features double-wall, powder-coated steel or 304/316 stainless steel construction — forming a robust, freestanding structure that integrates effortlessly into existing facilities.

Each panel is designed for maximum cleanliness, featuring smooth, non-porous surfaces that resist particle buildup and withstand rigorous cleaning protocols.

Add glass wall panels for full visibility and a bright, open workspace — eliminating the confined feel common to traditional cleanroom environments while maintaining strict contamination control.

Flexible Multi-Room Configurations

Whether you’re building a single aseptic space or a multi-suite biopharma facility, BioSafe® modular systems adapt to your needs.

Our pre-engineered wall and ceiling panels allow for complex, multi-room configurations including:

Airlocks and antechambers

Access-controlled doors and corridors

Dedicated gowning and preparation areas

Each system is engineered for easy expansion or reconfiguration — so your cleanroom can evolve as your research or production grows.

Smart Ceiling Grid System

The BioSafe® ceiling grid integrates seamlessly with essential cleanroom components, including:

HEPA and ULPA fan/filter units (FFUs) for precise air control

Fluorescent or LED lighting modules for optimal visibility

Ionizing bars or modules to minimize static buildup

This modular ceiling design ensures reliable airflow performance and easy integration with your HVAC, lighting, and monitoring systems.

Build Clean. Work Confident.

With BioSafe® Modular Cleanrooms, you get more than a clean space — you get a scalable, high-performance environment designed to support your mission in biopharma innovation, production, and safety.

📞 Contact us today to discuss your cleanroom project 416 332 8394 qc@perotech.com

Powder Containment Rooms

Durable, Easy-to-Clean BioSafe® Construction

Built with BioSafe® all-steel panels, these containment rooms feature a freestanding, easy-to-clean structure designed for high-level hygiene and long-term durability. Add optional ceiling-mounted filter/fan units to achieve cleanroom-grade air quality throughout the space.

Available in:

304/316 stainless steel for corrosion resistance and long service life

Powder-coated steel for a durable, cost-effective solution

Precision Airflow. Superior Containment. Cleanroom-Level Control.

Maintain a safe, contaminant-free environment during powder handling and weighing with Terra’s Powder Containment Rooms. Engineered for pharmaceutical, biopharma, and chemical applications, these modular containment systems deliver Class 100 (ISO 5) cleanliness with advanced air filtration and control.

Engineered for Operator Safety and Product Integrity

Each Powder Containment Room features a recirculating HEPA filtration module that continuously cleans the air to protect both the operator and the product.

Rear-mounted air vents efficiently pull powders and airborne contaminants away from the workspace, minimizing operator exposure.

Recirculation manifold channels air through inlet HEPA filters, maintaining a continuous wash of particle-free air across the work zone.

Integrated air conditioning and dehumidification modules ensure precise temperature and humidity control for sensitive materials.

A broad access area with parting vinyl strip shields allows easy material transfer — even pallet loading of large containers.

Cleanroom-Grade Containment Performance

Terra’s Powder Containment Room combines the benefits of a modular cleanroom with specialized HEPA filtration technology, maintaining cleanliness levels equivalent to Class 100 (ISO 5).

Experience reliable protection, easy maintenance, and complete environmental control — all in a scalable, modular design.

Modular Hardwall Cleanrooms

Freestanding, Durable, and Ready for ISO 5–8 Compliance

Terra’s Modular Hardwall Cleanrooms offer the strength and rigidity of a permanent structure with the flexibility of modular design. Each unit is factory-assembled and pre-tested to guarantee quick installation and long-term reliability.

Unlike traditional suspended systems, Terra’s Hardwall Cleanrooms are completely freestanding, eliminating the need for complex ceiling supports and reducing setup time.

Cleanroom Support Frame

The precision-engineered support frame uses interlocking 2″ (51 mm) powder-coated steel uprights and cross-sections for unmatched stability.

Ceiling members are welded to steel T-bars (3″ x 1.5″) forming 2′ x 4′ bays to support filters, fan units, and lighting modules.

Mirror-finished 304 stainless steel finishing strips secure panels and provide a clean, polished appearance.

Standard height: 7′ (2134 mm) from filter face to floor; 8’3″ (2530 mm) with filter/fan unit. Other custom heights available.

Hardwall Cleanroom Panels

Choose from a range of rigid, contamination-controlled panel materials to suit your cleanroom requirements:

Acrylic Panels

Provide full visibility, strength, and easy cleaning. Clear, black, or amber options available. (Not recommended for alcohol-based cleaning agents.)

Static-Dissipative PVC Panels

Ideal for ESD-sensitive or particle-critical applications. Molecularly bonded dissipative layers safely conduct surface charges to ground, preventing electrostatic buildup and particulate attraction.

Surface resistivity: 10⁶ – 10⁸ ohms/sq. cm (ASTM-D257).

Polycarbonate Panels

Deliver excellent chemical resistance and shatterproof strength. Withstand acids, solvents, and cleaning agents.

Polypropylene Panels

Provide superior resistance to acids and corrosive chemicals—ideal for wet processing environments.

Tempered Glass Panels

Offer crystal-clear visibility, broad chemical resistance, and non-porous surfaces for easy sterilization and long-term durability.

Why Choose Terra’s Modular Cleanroom Systems?

Freestanding, factory-tested structures for quick installation

Meets ISO 5–8 and GMP standards for cleanroom compliance

Configurable wall materials for optical clarity, chemical resistance, or ESD protection

Durable all-steel frame with welded T-bar grid for HEPA or ULPA filter support

Easy integration with Terra’s fan/filter units, lighting, and environmental controls

📞 Contact Your Terra Rep today qc@perotech.com

Build Safer, Cleaner Workspaces with Terra

Terra’s Powder Containment Rooms and Hardwall Modular Cleanrooms are trusted worldwide for precision, protection, and performance. Whether you’re handling hazardous powders or maintaining ISO-level cleanliness, Terra delivers scalable solutions built for your industry.

Enter the Cleanroom and Leave Your Particles Behind! Each unit is fully equipped with a protected passageway that allows a large number of personnel to pass into controlled areas without sacrificing convenience or cleanliness.

📞 Contact Your Canadian Terra Rep today to request a quote or discuss your cleanroom project. qc@perotech.com

Air Showers & Tunnels

Maximize Contamination Control and Cleanroom Safety

Terra’s Air Showers and Tunnels deliver powerful, Class 100 (ISO 5) clean airflows to remove surface particles and prevent contamination from entering your controlled environment. Each system combines high-velocity airflow, HEPA filtration, and intelligent controls to ensure superior particulate removal and operator safety in every cycle.

High-Velocity Clean Airflow for Maximum Decontamination

During each cycle, pressurized air streams from adjustable nozzles at speeds of up to 8,000 feet per minute (41 m/s)—scrubbing contaminants from garments, tools, and surfaces in seconds.

Uniform nozzle placement on the walls and ceiling ensures complete 360° coverage.

The lowest nozzle, positioned 19″ (483 mm) from the floor, directs airflow to reach every surface effectively.

The closed-loop circulation system captures airborne particles, directing contaminated air downward into wall plenums before recirculating it through HEPA filters that remove 99.97% of particles ≥ 0.3 microns.

This constant filtration process maintains particle-free air and prevents contaminants from entering the cleanroom.

Intelligent Door Control Prevents Cross-Contamination

Electromagnetic interlocking doors prevent simultaneous entry and exit, stopping contaminated air from flowing between the air shower and the cleanroom.

Doors automatically unlock during power loss or when the emergency stop button is pressed, ensuring user safety.

LED ceiling lighting provides bright, even illumination while maintaining optimal airflow circulation.

Smart Touch-Screen Control Panel

Each Air Shower and Tunnel includes a solid-state microprocessor control panel that simplifies operation and enhances security.

Adjust cycle durations and set entry/exit delay times for precise contamination control.

Run Time tracking helps schedule filter replacements and routine maintenance.

Built-in diagnostics monitor the performance of blowers, door locks, and switches to ensure consistent reliability.

The touch-screen interface makes system operation intuitive, fast, and secure—ideal for both large-scale and small cleanroom installations.

Clean, Durable Construction

Choose from two high-performance materials to match your cleanroom environment:

Powder-coated steel – durable, economical, and easy to maintain

304 stainless steel – corrosion-resistant and ideal for critical biopharma or aseptic applications

All models include anodized aluminum access doors with transparent SDPVC panels for visibility, durability, and full compliance with cleanroom protocols.

Why Choose Terra’s Air Showers & Tunnels?

Removes surface contamination before personnel enter controlled areas

Ensures ISO 5 (Class 100) cleanliness with high-efficiency HEPA filtration

Prevents cross-contamination between gowning and cleanroom zones

Customizable configurations to fit your space and personnel flow

Energy-efficient blower system reduces operating costs

Safe, ergonomic design with LED lighting and smart automation

Create a Cleaner, Safer Facility

Terra’s Air Showers and Tunnels combine advanced airflow engineering with intelligent automation to safeguard your cleanroom from contamination. Whether you need a single-entry air shower or a multi-person air tunnel, Terra delivers precision-built solutions for every industry—from pharmaceutical manufacturing to semiconductor fabrication.

Simplex Cleanrooms and Components

Phone 416 332-8394 for pricing Email: qc@perotech.com

The hallmark of Simplex products, especially AirLock enclosures and cleanrooms, is modularity. All of the products manufactured by Simplex are designed to be modular and expandable. Your need for clean manufacturing space may be small at first – an 8′ x 10′ or a 10′ x 12′ may suffice. But as your business grows and your needs expand, your original Simplex enclosure can expand with those needs.

AirBlock softwalls are constructed from four-foot wide sheets of vinyl in thicknesses from 40 to 80 mil, RF welded to form either solid walls or movable curtains. They are especially suitable for enclosing portable frame systems or improving laminar flow areas above work spaces.

The Simplex SIS Modular Frame System is built around simple, strong, easy to assemble modules. You can quickly assemble three or four sided modular sections and latch or screw them together. It’s that simple! Modules can be disassembled or expanded as your needs change.

Outfit the SIS 212 enclosure with optional casters and you have an enclosure you can move around the shop floor wherever you need to guard a process from contamination.

Easy-to-clean features are ideal for USP 797 applications, such as pharmaceutical compounding, medical device manufacturing, assembly and sterile packaging.

We can design 797 cleanrooms to meet the requirements of Chapter 800, requiring that some hazardous drugs are treated in negative pressure cleanrooms. We can also engineer enclosures that include both negative and positive pressure rooms, as well as a gowning room so that technicians can safely transfer between rooms and control contamination issues.

The standard Airlock ceiling is a fully integrated 2” T-bar shipped in prefabricated modules. The modules come complete with gaskets and can accept standard 2′ x 4′ ceiling panels. Threaded rod suspenders support ceiling frames or struts from any existing structure for larger rooms of any size. Ceiling loads are limited only by the number of attachments and the strength of the existing ceiling.

Proven Performance. Rapid Payback.

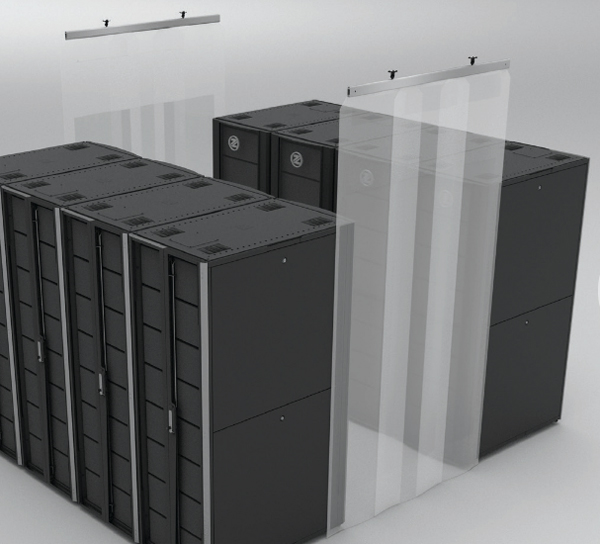

Simplex AirBlock™ Containment Systems are trusted by data center managers worldwide to optimize cooling efficiency, reduce energy consumption, and protect mission-critical IT infrastructure.

By improving airflow management, you’ll extend equipment lifespan, reduce downtime, and cut costs—without expensive facility renovations.

Data Center Air Containment Solutions

Slash Energy Costs and Maximize Cooling Efficiency with AirBlock™

Optimize your data center airflow and protect mission-critical systems with Simplex AirBlock™ Containment Solutions. Engineered for hot aisle/cold aisle isolation, AirBlock™ systems reduce air conditioning costs by up to 67%, stabilize rack temperatures, and deliver an average ROI in just one year.

Whether you’re managing a hyperscale facility or a small enterprise server room, AirBlock™ helps you increase capacity, improve cooling performance, and extend the life of your IT equipment—all while cutting operational expenses.

Why Choose AirBlock™ for Your Data Center?

⚙️ Reduce Energy Costs: Lower HVAC energy consumption by up to 67% through improved airflow containment.

🌡️ Stabilize Temperatures: Maintain cooler, more consistent rack environments for optimal equipment performance.

🚀 Increase Capacity: Maximize existing infrastructure without expanding your cooling systems.

💰 Fast ROI: See measurable savings and payback in as little as 12 months.

🔒 Protect Mission-Critical Operations: Prevent hot air recirculation and reduce equipment failures.

Flexible Solutions for Any Data Center Configuration

Simplex AirBlock™ offers a complete line of modular airflow management products, including:

Curtains and Partitions – Flexible, modular, and easy to install for rapid deployment.

Ceiling Panels and Strip Doors – Create effective separation between hot and cold aisles.

Mounting Systems – Adapt to any rack layout or ceiling structure for a customized containment solution.

Each component integrates seamlessly to create efficient hot aisle/cold aisle isolation, optimizing your cooling efficiency and airflow dynamics.

The Pro-Glide™ Modular Sliding Door

Designed Specifically for Data Center Airflow Control

The Pro-Glide™ Modular Sliding Door combines sleek aesthetics with advanced engineering to provide the most efficient and attractive door system for data center containment.

Key Features:

Smooth, reliable sliding operation for high-traffic areas

Tight seals to prevent air leakage and maintain temperature control

Modular design for easy installation and maintenance

Durable materials engineered for long-term performance

The Pro-Glide™ door completes your AirBlock™ containment system, enhancing airflow efficiency while maintaining easy access for technicians.

Build a Cooler, Smarter Data Center

Join the industry leaders who rely on AirBlock™ to maintain uptime and efficiency.

📞 Contact Your Simplex Rep today to request a free airflow analysis or project consultation. qc@perotech.com

SubZero/Simplex designs and manufactures strip doors from the smallest application–a door in your manufacturing area–to the largest of applications–guarding the truck doors on your loading docking, or even the giant door where you back in freight cars for loading and unloading in your warehouse.

Simplex Industrial Strip Doors protect against contamination in cleanroom environments. Specify anti-static strips for electronics manufacturing, or use our heavy-duty strips on warehouse loading docks to keep out dust, birds and insects. Whatever your manufacturing or warehousing challenge when it comes to environmental control, Simplex has a solution for you.

CleanLine™ Modular Cleanroom Systems

Flexible, Scalable, and Cost-Effective Cleanroom Construction

Create the clean environment your process demands with CleanLine™ Modular Cleanroom Systems — the ultimate solution for ISO 4 to ISO 8 cleanroom environments. Engineered for flexibility and precision, CleanLine™ delivers the performance of permanent construction at a fraction of the cost and installation time.

From critical process control to basic environmental partitioning, CleanLine™ provides a clean, professional, and fully customizable solution for your facility.

All-Purpose Modular Cleanroom Design

The CleanLine™ System is an all-in-one modular platform designed to meet a wide range of cleanroom and controlled-environment applications. Whether you need to control airborne contamination, temperature, humidity, or pressure, CleanLine™ adapts seamlessly to your requirements.

Supports ISO Class 4–8 cleanroom configurations

Provides precise control over environmental parameters

Delivers faster installation and lower cost than traditional construction

Ideal for life sciences, microelectronics, aerospace, and pharmaceutical manufacturing

High-Performance Cleanroom Walls and Panels

The CleanLine™ post-and-panel system offers three distinct wall sizes that can be combined to create a cohesive, functional cleanroom layout.

Extruded aluminum frames provide strength, precision, and long-term durability.

Ultra-smooth wall surfaces support maximum cleanliness and easy sanitization.

Modular wall panels serve as an effective alternative to conventional construction, meeting the most demanding cleanliness and performance requirements.

Each system is engineered for aesthetics, adaptability, and compliance, ensuring your cleanroom maintains a consistent, professional appearance.

Designed for Maximum Flexibility

CleanLine™ Cleanroom Systems are engineered to evolve with your operation.

Install as freestanding envelope structures or floor-to-ceiling systems that connect directly to your facility ceiling or grid.

Integrate load-bearing platforms to support mechanical or maintenance equipment.

Modify or expand walls at any time with demountable panel construction—without disrupting adjacent walls or ceiling structures.

This modular design gives you complete control over layout, workflow, and scalability as your cleanroom needs grow or change.

Faster, Smarter, and More Sustainable

Unlike traditional construction, CleanLine™ modular cleanrooms minimize waste, reduce installation time, and lower lifecycle costs. Every panel and component is prefabricated for quick on-site assembly, allowing you to meet deadlines and compliance standards faster.

PortaFab’s modular approach ensures your investment remains flexible, compliant, and future-proof, even as your technology or processes evolve.

Why Choose CleanLine™ Modular Cleanrooms?

Engineered for ISO 4–8 environments

Customizable configurations for cleanrooms or process enclosures

Durable aluminum frame construction with smooth, cleanable surfaces

Freestanding or integrated installation options

Expandable and reconfigurable design for long-term adaptability

Faster, lower-cost installation than traditional construction methods

Build Your Cleanroom with Confidence

Whether you’re designing a new cleanroom or upgrading an existing facility, CleanLine™ Modular Cleanroom Systems deliver the precision, performance, and flexibility you need — with faster turnaround and proven ROI.

📞 Contact Your PortaFab Rep today to discuss your cleanroom project or request a custom quote. qc@perotech.com

Cleanline S3000 Wall System

The S3000 3″ thick cleanroom wall system is the perfect solution when a free-standing cleanroom envelope with a plenum cap is required and the design criteria do not allow the cleanroom to tie into an existing structure where the ceiling can be supported. The systems load-bearing roof provides support of mechanical equipment.

- 3″ (76mm) wall panel system with wiring raceway

- Load-bearing roof capabilities

- Available in heights up to 18′ tall

- All aluminum framework

P2000 Wall System

The CleanLine P2000 is a 2″ thick wall system that provides the benefits of a partition system for interior walls, plenum chase returns, and column enclosures.

- 2″ (50mm) wall panel system with wiring raceway

- Available in heights up to 12′ tall

- Integrates with the FabLine wall system

- All aluminum framework

PM458 XTRA TALL Wall System

The PM458 system features extra height walls that can extend to your existing ceiling or be freestanding with load-bearing decks. The simple, fast installation of the PM458 minimizes plant disruption while the variety of core materials and panel finishes allow you to meet requirements for acoustic and thermal insulation, chemical resistance, and static control.

- 4-5/8″ (117mm) wall panel system with wiring raceway

- Load-bearing roof capabilities

- Available in heights up to 24′ tall

APPLICATIONS

Controlling environmental conditions in an entire industrial facility can be costly and difficult. With PortaFab modular systems, critical environments can be constructed quickly and easily to house specific manufacturing or assembly processes. Common applications include inspection rooms and finishing and packaging areas, but any process requiring environmental control over critical temperature, humidity, or particulate of any kind is viable.

For Quotations and Technical: qc@perotech.com 416 332-8394

Gown rooms or environmentally controlled changing areas are essential for cleanrooms that must meet more stringent air quality guidelines. These gown rooms are typically outfitted with cleanroom benches and cleaning stations and feature air shower entryways.

For Quotations and Technical: qc@perotech.com 416 332-8394

Achieve USP 800 Compliance with PortaFab Cleanroom Systems

In March of 2014 USP (United States Pharmacopeial Convention) proposed new general chapter “800”, also referred to as USP 800. This new chapter applies to all personnel that compound hazardous drug preparations, as well as all places where hazardous drugs are prepared, stored, transported and administered in order to protect healthcare workers, patients and the environment.

For Quotations and Technical: qc@perotech.com 416 332-8394

PortaFab animal housing labs and vivarium facilities are designed to integrate with operative research equipment. Our modular labs are designed to meet your requirements providing an effective alternative to conventional construction reducing costs, mess and time delays. The labs provide flexibility and can be modified or moved to expand with facility needs.

For Quotations and Technical: qc@perotech.com 416 332-8394

PortaFab has partnered with several cannabis cultivation lab design and build companies in major US markets including Denver, Washington DC, Oregon and Los Angeles to provide efficient and quality marijuana grow rooms within this expanding industry.

For Quotations and Technical: qc@perotech.com 416 332-8394

PortaFab Modular Building Systems are an ideal solution for quickly creating temporary, semi-permanent, and permanent isolation rooms within hospitals and medical centers. As a Clean Build alternative to traditional construction, PortaFab’s pre-engineered systems require minimal onsite cutting and fabricating which minimizes contamination threats and helps comply with Class IV ICRA guidelines.

For Quotations and Technical: qc@perotech.com 416 332-8394

PortaFab’s machine enclosures provide environmental control from noise, temperature, humidity and particulates. Whether you need a cleanroom to house an injection molding machine making medical products or simply want to reduce noise pollution caused by machinery in your plant, our Cleanroom and Modular Wall Systems can be used to achieve the conditions your applications require.

For Quotations and Technical: qc@perotech.com 647 268-6306

Additional Applications

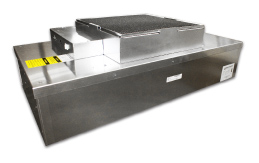

Terra HEPA Filter Fan Module

Internal baffling plates and anodized aluminum diffuser panel provide uniform air speed across the filter face, ensuring laminar airflow

- Low-profile design allows cleanroom installation inside rooms with standard 9-foot (2743 mm) ceilings

- Quiet, low-vibration design: only 50 dBA, measured 30″ (762 mm) from filter face @ 90 FPM (0.5 m/s)

HEPA and ULPA Filtration Options

Choose from two high-efficiency filtration options for your specific application:

HEPA Filters: 99.99% efficiency at removing particles ≥ 0.3 microns.

ULPA Filters: 99.999% efficiency at removing particles ≥ 0.12 microns.

These filters deliver unmatched particulate control and long service life, helping you maintain an ultra-clean environment while reducing maintenance demands.

Built for Durability and Cleanroom Compatibility

The housing is constructed from powder-coated cold-rolled steel (CR steel) for corrosion resistance and long-term durability. For more demanding environments, an optional Type 304 stainless steel housing provides additional chemical resistance and extended longevity.

Every design element — from airflow balance to filtration efficiency — works together to ensure a quieter, cleaner, and more energy-efficient cleanroom experience.

High-Performance Fan/Filter Units – Clean, Consistent, and Reliable Airflow

Engineered for precision and reliability, our self-powered Fan/Filter Units (FFUs) deliver consistent, microfiltered air to meet stringent cleanroom standards down to Class 10 (ISO 4). Designed for continuous 24/7 operation, these advanced systems ensure superior air purity, uniform airflow, and low maintenance for critical environments.

Powerful and Consistent Airflow

Each unit provides an average airflow velocity of 90+ feet per minute (0.45+ m/sec) and a total airflow of 640+ CFM (1088 m³/hr) under filter load at the 100% medium setting (2′ x 4′ model).

This ensures clean, laminar air distribution across your controlled space, optimizing cleanliness and process performance.

In addition, a three-speed control switch (high/medium/low) allows effortless airflow adjustment, while the optional EnergySaver Remote Control System simplifies air balancing and energy optimization across multiple units.

Compliant and Proven Performance

All models are manufactured to meet IEST Recommended Practices and can be configured according to Application Guidelines to meet specific requirements for cleanliness and lighting. Whether your goal is to improve ISO certification or maintain critical air quality, our FFUs deliver the consistency your operations demand.

Precision Engineering for Uniform Airflow

Our fan/filter units use a centrifugal-type fan/motor assembly with permanently lubricated bearings for quiet, long-lasting operation. The unit’s housing — crafted from durable powder-coated steel — integrates a drop-in prefilter (optional stainless steel available) for easy serviceability and long-term dependability.

Through advanced baffling technology, the system ensures even air velocity across the entire filter face, minimizing turbulence while significantly reducing operational noise.

Call 416 332-8394 for pricing and delivery. qc@perotech.com

MAC 10® LE-DC Fan Filter Unit

MAC 10® LE-DC – The Next Generation Fan Filter Unit (FFU)

Building on decades of cleanroom innovation, Envirco® proudly introduces the MAC 10® LE-DC, the second generation of our industry-leading Fan Filter Unit (FFU) family. Designed for precision airflow control, energy efficiency, and intelligent connectivity, the MAC 10® LE-DC sets a new benchmark in cleanroom air filtration performance.

While Envirco® has pioneered numerous proprietary technologies, the MAC 10® series remains one of our most successful product lines. Now, with the LE-DC model, we elevate performance and flexibility even further — offering the most advanced control options and the most versatile system available on the market today.

⚙️ Standard Features – Engineered for Excellence

1. Universal Control Card for Total Flexibility

Seamlessly transition between multiple control modes with our new Universal Control Card, which supports:

Network Speed Control (MODBUS RTU) for advanced automation integration

On-Board Potentiometer for precise manual speed adjustment

Analog Speed Control (Remote 0–10V) for customized system management

This innovative control platform empowers users to adapt the FFU operation instantly to evolving cleanroom requirements — ensuring total flexibility and efficiency in any environment.

2. EC Brushless Motor for Energy-Efficient Operation

At the heart of the MAC 10® LE-DC lies an Electronically Commutated (EC) brushless motor equipped with an internal microprocessor. This intelligent design optimizes performance, reduces energy consumption, and extends the operational lifespan of the unit.

The result? Quiet, reliable, and maintenance-free operation — ideal for mission-critical cleanroom applications.

3. High-Performance Air Filtration

Every unit features a High-Efficiency Particulate Air (HEPA) filter, rated 99.99% efficient at 0.3 microns, delivering consistent ISO Class 4 (Class 10) cleanroom-level air quality.

For environments demanding even greater precision, ULPA filter options are also available.

4. Superior Design and Construction

Built to last, the MAC 10® LE-DC incorporates:

Duct Collars (10″, 12″, 14″) for direct HVAC integration

Backward-Inclined Centrifugal Fan for stable, uniform airflow

1.0 in. wg (200 Pa) external static capability for powerful performance

Washable Pre-Filter to extend main filter life and reduce costs

Walkable Plenum (excluding prefilter) rated to 250 lbs for easy maintenance access

Mill-Finished Aluminum Housing for durability and corrosion resistance

Every component is manufactured to IEST recommended practices and rigorously tested to guarantee long-term reliability and cleanroom compliance.

5. Multiple Configurations for Any Space

Available in 2×2, 2×3, 2×4, and 4×4 sizes, the MAC 10® LE-DC easily integrates into modular cleanroom systems or custom installations.

Additionally, it’s cUL listed (115V, 208–240V, 277V) with standard UL 900 filters (file number E152685 UL507), ensuring full safety certification and compliance.

✅ Why Choose the MAC 10® LE-DC?

Advanced universal control options for maximum system flexibility

Low energy consumption with EC brushless motor technology

HEPA filtration that meets the most demanding cleanliness standards

Durable, walkable construction for safe maintenance

Multiple sizes and voltage options for seamless integration

Fully compliant with international cleanroom standards

Experience the power of precision with the MAC 10® LE-DC — the smarter, quieter, and more energy-efficient Fan Filter Unit built for the cleanrooms of tomorrow.

A Green Product Solution – Energy Efficiency Redefined

The MAC 10® LE-DC Fan Filter Unit (FFU) isn’t just built for performance — it’s designed for sustainability. By combining cutting-edge EC motor technology with Envirco’s proprietary baffling system and backward-inclined fan design, this next-generation FFU leads the industry in both energy efficiency and environmental responsibility.

Because of its sustainable design, the MAC 10® LE-DC can also help your facility earn valuable LEED points, contributing to certification under the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) program.

♻️ Engineered for Maximum Efficiency and Minimal Impact

Through decades of innovation, Envirco® has mastered the art of balancing performance with responsibility. The LE-DC leverages a high-efficiency Electronically Commutated (EC) motor with an internal microprocessor to deliver:

Exceptional energy savings, consuming as little as 90W at 90 feet per minute (fpm)

Superior airflow performance with consistent pressure control

Extended motor life and reduced operational costs

Moreover, the system’s proprietary baffling design and backward-inclined fan minimize turbulence and maximize laminar airflow, ensuring a clean, consistent, and quiet environment.

🔇 Quiet Operation, Proven Performance

Transitioning from traditional FFUs to the MAC 10® LE-DC means gaining a cleaner, quieter workspace. Operating at just 52.3 dBA, the LE-DC maintains one of the lowest noise levels in the industry — a hallmark of the MAC 10® family.

This whisper-quiet performance not only supports technician comfort but also contributes to overall facility well-being and compliance with noise-sensitive research or production environments.

🌍 Global Performance, Local Impact

Trusted worldwide, Envirco® MAC 10® FFUs power countless critical cleanroom applications — from biotechnology and pharmaceuticals to semiconductor and microelectronics manufacturing. Wherever clean air is mission-critical, the LE-DC delivers proven, energy-smart performance that reduces your environmental footprint without compromising quality or reliability.

⚙️ Optional Features – Tailored for Every Cleanroom Need

Customize your MAC 10® LE-DC to fit your specific cleanroom requirements. Available options include:

Room-Side Replaceable Filter (RSR) for simplified maintenance

Room-Side Replaceable Filter and Motor Assembly (RSRE) for full modular serviceability

Infrared Speed Control for effortless airflow adjustment via hand-held remote

Ducted Inlet Connection (10″, 12″, or 14″) for direct HVAC integration

Flow-Through Light Fixture for illumination with minimal airflow disruption

Powder-Coated White or Stainless Steel Housing for aesthetic and durability options

Room-Side 3/8″ Challenge Ports for convenient HEPA filter testing (standard on RSE and RSRE units)

ULPA Filter (99.9995% at 0.12 microns) with PTFE media and low boron content for ultra-clean environments

3/4″ Knife Edge for quick placement in gel track ceiling grid systems (available on RSR and RSRE)

MERV 8 Pre-Filter for enhanced particulate capture

CE Certified (230V units) for compliance in international markets

🌱 Choose MAC 10® LE-DC – The Sustainable Cleanroom Solution

By integrating advanced airflow technology, ultra-efficient EC motors, and eco-conscious engineering, the MAC 10® LE-DC represents the future of sustainable cleanroom design. From reducing power consumption to enhancing LEED certification potential, this unit helps organizations achieve cleaner air, lower costs, and a greener footprint — all without compromise.

Step into the next generation of clean air performance. Choose the MAC 10® LE-DC — where precision meets sustainability.

MAC-10-LEDC PDF MAC-10-LEAC

MAC 10 IQ_ MAC-10-Controllers

MAC-T Ceiling Grid System – Precision, Strength, and Cleanroom Compatibility

Engineered for performance and reliability, the Envirco® MAC-T Ceiling Grid System delivers exceptional strength and flexibility for controlled environments. Designed with precision, this 2-inch Gasket Seal Grid Cleanroom Ceiling System combines superior materials and innovative engineering to provide both a robust structural framework and zinc alloy die-cast connections that ensure long-term durability and stability.

Built for seamless integration, this extruded aluminum ceiling system offers cost-effective performance across a range of cleanroom classifications — from ISO 8 (Class 100,000) to ISO 5 (Class 100) — and is ideal for full HEPA coverage applications.

⚙️ Designed for Flexibility and Reliability

Every cleanroom ceiling system depends on the quality of its connection and suspension components, and Envirco’s system sets the standard. The MAC-T Ceiling Grid System features a true, extruded aluminum 2-inch profile, ensuring easy installation and long-lasting support.

Furthermore, the rod-suspended configuration provides unmatched adaptability, allowing you to tailor your setup for specific operational or architectural requirements. Whether you’re designing a new facility or upgrading an existing one, customization is simple, efficient, and worry-free.

➡️ Transition seamlessly from planning to installation with the support of Envirco’s expert engineering team. Contact us today to discuss configurations that perfectly align with your cleanroom’s specifications.

🧩 Advanced Design Features for Superior Performance

The MAC-T Gasket Seal Grid Ceiling System incorporates multiple design innovations that enhance both functionality and ease of assembly:

Continuous ¼-20 threaded channels for effortless connection and suspension at any point

Lightweight, multi-purpose connectors that securely join grid members

Integrated suspension points for threaded rods or wire-hung eye bolts

2-inch wide extruded aluminum flange for mounting HEPA filters, ceiling tiles, and light fixtures

Compatible with cleanroom lights designed for 2” grids or teardrop light fixtures

Available in both adjustable turnbuckle and eye bolt suspension configurations

Full 2-inch face for maximum surface contact and stability

Durable white polyester finish, stronger and longer-lasting than standard powder coating

Zinc alloy castings for added rigidity and corrosion resistance

Center Line of Grid: 24½” x 48½”

Module, Fixture, and Tile Size: 23⅝” x 47⅝”

💡 Built for Efficiency and Ease of Use

In addition to its strength, the MAC-T Ceiling Grid System was designed with simplicity in mind. Each component fits together effortlessly, enabling quick installation and minimal maintenance. The modular design supports rapid reconfiguration and easy integration with lighting and filtration systems, ensuring your cleanroom remains compliant, adaptable, and future-ready.

🌐 The Smarter Choice for Cleanroom Infrastructure

From pharmaceutical facilities to semiconductor manufacturing and biotechnology labs, the MAC-T Ceiling Grid System offers a proven solution that combines precision engineering, clean aesthetics, and lasting performance.

When your cleanroom demands structural integrity and airflow precision, choose Envirco® — the trusted name in cleanroom technology.

Terra Universal Pass Through

Shutting the Door on Contamination

These Pass-Through Chambers cut down significantly on traffic and contamination by providing a better, safer way to transfer equipment and paperwork.

Low-Maintenance Reliability

The no-maintenance interlock system operates purely mechanically — with no need for electricity, gas, or external connections. Therefore, it continues to function seamlessly even during system shutdowns or power outages, ensuring continuous protection and reliability.

✅ Key Benefits at a Glance

Constructed from 304 stainless steel or powder-coated steel for long-lasting performance.

Optional UltraClean™ electropolished finish for the most stringent particle control.

Available in polypropylene, PVC, and static-dissipative PVC for chemical and ESD-sensitive applications.

Mechanical interlock system prevents cross-contamination — no power or maintenance required.

Compatible viewing windows provide visibility without compromising cleanliness.

Engineered to support ISO cleanroom compliance and GMP standards.

Cleanroom Pass-Throughs – Engineered for Contamination Control and Durability

Maintain the integrity of your controlled environment with precision-engineered cleanroom pass-through chambers. Built from 304 stainless steel or durable powder-coated steel, these pass-throughs ensure clean, reliable operation in every application.

For facilities requiring the highest particle control, upgrade to the UltraClean™ electropolished 304 stainless steel pass-through, designed for exceptional surface smoothness and easy sterilization.

Versatile Material Options for Every Application

To meet the diverse needs of laboratory and cleanroom environments, we offer multiple material configurations:

Polypropylene and PVC Models: Ideal for chemical handling applications where corrosion resistance is critical.

Static-Dissipative PVC Models: Combine excellent chemical resistance with superior static control, offering a surface resistivity of approximately 10⁷ ohms/square to minimize particle attraction and buildup.

Viewing Windows: Each pass-through includes clear, durable windows made from materials compatible with the unit’s construction, ensuring excellent visibility and chemical stability.

Enhanced Contamination Prevention Through Smart Design

Every unit is equipped with dual mechanical interlocking doors to maintain strict contamination control. This intelligent interlock system ensures that only one door opens at a time, preventing cross-contamination and limiting the volume of air exchanged between rooms.

As a result, airborne particle transfer is minimized, keeping your cleanroom environment stable and compliant with critical cleanliness standards.

Optimize your cleanroom workflow with high-performance pass-through chambers that ensure efficiency, durability, and total contamination control — all built to last and engineered to protect.

![]() Pass-Through Selection Video Terra Pass-Through Website phone 416 332-8394 for pricing or: qc@perotech.com

Pass-Through Selection Video Terra Pass-Through Website phone 416 332-8394 for pricing or: qc@perotech.com

Air Curtains mount above an entryway to produce a barrier of ULPA micro-filtered air. They protect against against particles and ambient air from entering a controlled environment. Similar to a door, an air curtain acts as a barrier between two rooms or spaces to control temperature and prevent hot/cool air from entering or escaping.

Inexpensive alternative to Air Showers, removes particles from personnel and parts entering a clean room.

Ideal for doors frequently opened or doorless entryways.

Two operating modes: motion sensor activation (with adjustable delay) or continuous operation (fixed speed)

Adjustable baffles to change angle of discharge port (±30°)

Continuous flow of air can be positioned over conveyor belts or automated processes that move between rooms

Customizable to fit any entryway or wall opening

Terra Universal Air Shower

Enter the Cleanroom and Leave Your Particles Behind! Each unit is fully equipped with a protected passageway that allows a large number of personnel to pass into controlled areas without sacrificing convenience or cleanliness.

Air Showers and Tunnels supply concentrated Class 100 clean airflows to lift off contamination while an individual occupies the air enclosure. Whenever the shower cycle commences, pressurized air streams from adjustable nozzles at a velocity of up to 8,000 feet per minute (41 m/s). This ensures the necessary efficient scrubbing action to remove particulate matter.

Air nozzles are arranged on the walls and ceilings in a uniform pattern to ensure effective distribution of filtered air; the lowest nozzle is positioned 19″ (483 mm) off the floor. The closed-loop circulation design directs contaminated air downward through the vents and wall plenums of the Air Shower/Tunnel and back to the HEPA filter, which removes 99.97% of all particles as small as 0.3 microns.

Electromagnetic interlocking doors prevent unnecessary contamination inflow and thereby prevent cross-contamination of the cleanroom and the Air Shower/Tunnel. They automatically release in the event of a power failure or at the press of the emergency stop button to ensure operator safety. LED lighting, built into the ceiling to allow unimpeded air circulation, ensures full visibility no matter what size or configuration you select.

Touch Control

Touch-Screen Control Panel Enhances Convenience and Security. Each unit includes a solid-state microprocessor panel (located at the front entrance) that controls shower cycle durations and entrance/exit delay times. A Run Times feature is also included to help you set and maintain a filter-replacement schedule based on your maintenance protocol.

This system includes full microprocessor diagnostic capabilities, covering operation of the blower, door switch, and door lock.

Clean, Durable Construction Select models in one of two materials to suit your cleanroom requirements: white powder-coated steel or 304 stainless steel. All models feature anodized aluminum access doors with transparent SDPVC panels.

![]() Air Shower Video Terra Air Shower and Tunnel Website Call 416 332-8394 for pricing and delivery

Air Shower Video Terra Air Shower and Tunnel Website Call 416 332-8394 for pricing and delivery

Click on brochure to the left for PDF and access to USA budget pricing and ordering info.

For Canadian sales please contact QC at: qc@perotech.com or 647 268-6306