Custom and Complementary Products

Stainless Steel Carts and Cabinets

Cannabis Production Equipment

CANNABIS PRODUCTION EQUIPMENT

Why Growers Choose METRO

Proven Industry Expertise – Over eight decades serving critical industries.

Durable, Easy-to-Clean Designs – Engineered for cleanliness and longevity.

Optimized Facility Efficiency – Modular systems designed for space and productivity.

Trusted by Global Growers – Used by some of the largest cultivators worldwide.

Precision Equipment for Every Step of Cannabis Production

At METRO, we firmly believe that the process defines the product. Consequently, selecting the right equipment is absolutely essential for cultivating premium cannabis that your customers will not only love but also trust. Leveraging over 80 years of expertise from the scientific, healthcare, and foodservice industries, we are now applying our proven standards of process perfection directly to the cannabis market.

Furthermore, we have already partnered with some of the world’s largest cannabis growers, delivering innovative solutions that actively maximize crop yield, streamline operations, and enhance overall facility efficiency. Therefore, whether you are growing, drying, or storing, METRO provides robust systems designed to support every single production stage with unmatched quality and reliability.

Optimize Cannabis Growth & Storage

Engineer Smarter Storage for Vegetative and Flowering Rooms

While vegetative and flowering areas require stable environmental controls, intelligent storage is equally critical. For this reason, METRO’s customizable polymer carts and shelving systems are specifically engineered to improve workflow while simultaneously protecting plant health.

First, the corrosion-resistant polymer construction guarantees long-lasting performance.

Additionally, built-in antimicrobial protection actively inhibits mold, mildew, and bacteria growth.

Finally, easy-to-clean, mobile designs drastically simplify sanitation and enhance facility organization.

Featured Growth & Storage Products

Super Erecta® MW Series Utility Carts

These durable and versatile utility carts combine sturdy stainless steel with practical chrome wire shelving. Moreover, each unit ships compactly for your convenience and is built for long-term reliability.

Top-Track™ High-Density Storage Systems

Maximize your valuable grow room footprint with our Top-Track Shelving. As a result, our easy-order kits facilitate fast, efficient setup while keeping floors clear and easy to clean. Ultimately, you gain significant storage capacity without sacrificing accessibility.

Enhance Cannabis Drying & Curing

Achieve Controlled Drying for Unmatched Consistency and Quality

The drying and curing process directly determines your product’s final potency, flavor, aroma, and shelf life. That’s why METRO’s drying solutions provide precise command over airflow, temperature, and humidity to ensure every batch delivers consistently high-quality results.

Select from specialized tray or hanging drying racks tailored to your unique workflow.

Actively optimize your drying room’s environment for superior preservation.

Significantly reduce contamination risks by using clean, corrosion-resistant materials.

Because every operation is unique, our team collaborates closely with you to design a fully custom drying solution. This ensures your buds remain potent, safe, and perfectly market-ready.

Partner with METRO to Perfect Your Process

From cultivation and drying to storage and workflow optimization, METRO delivers powerful equipment that empowers your facility to perform at its absolute best. Therefore, by choosing METRO, you are committing to a safer, more efficient, and sustainable future for your business.

📞 Contact us today to learn how METRO can help you elevate your cannabis production environment. qc@perotech.com

Trimming

Revolutionize Your Trim and Packaging Workflow

Trimming consistently ranks as one of the most demanding jobs in the cannabis industry. Consequently, we specifically set out to engineer an ergonomic solution that directly supports your team. METRO’s trimming tools are designed for peak effectiveness and efficiency, allowing you to significantly boost both trimmer productivity and overall production output.

Similarly, the packaging process requires meticulous care, with specialists responsible for the final manicuring and packaging of both plant material and infused products. Therefore, maintaining a perpetually clean and sterile production environment is absolutely critical. This is precisely what we provide: integrated solutions that guarantee a hygienic workspace, safeguard product integrity, and streamline your entire operation from trim to shipment.

METRO HD Super

Stainless Steel Worktables: Engineered for Cleanliness & Efficiency

Build a more hygienic and stable production line with METRO’s Stainless Steel Worktables. Specifically designed for demanding environments, they feature a seamless 14-gauge Type 304 stainless steel surface that resists corrosion and simplifies cleaning.

Furthermore, we’ve engineered these tables for immediate productivity. For instance, they are shipped knocked down and can be assembled in minutes without any tools required.

You have two options tailored to your workflow:

Stationary Worktables: Provide a solid, reliable foundation at a standard 34″ (864 mm) height, complete with adjustable leveling feet for perfect stability on any floor.

Mobile Worktables: Alternatively, choose mobility for dynamic production areas. Also standing 34″ high, these tables include four 5″ poly casters (2 swivel and 2 with brakes) for easy movement and secure positioning.

In short, whether you need stationary stability or flexible mobility, METRO worktables deliver the durable, cleanable surface your facility requires.

Secure Storage

Cloning

Benefits of METRO

Gowning

Cannabis grow facilities are required to have a gowning room. Gowning rooms provide a space for workers and visitors to put on face masks, hairnets, gloves, and coveralls before entering growing and processing areas. These additional safety measures protect the plants in the facility from bacteria, fungus, mold, and other contaminants. The most important thing when outfitting this space with furniture is cleanliness.

METRO Catalog click here More info and pricing: email qc@perotech.com

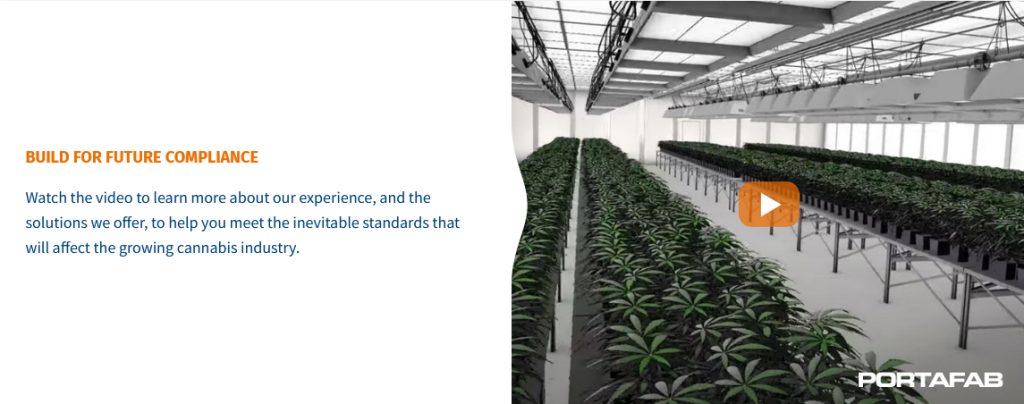

Modular Cleanroom Solutions for the Cannabis Industry

Trusted Global Expertise. Proven Pharmaceutical Standards.

As a global leader in modular cleanroom systems, PortaFab already empowers the pharmaceutical, medical, and food processing industries with clean, compliant, and scalable environments. Now, we are proud to bring this same proven expertise to the rapidly growing cannabis industry, helping you meet the rigorous standards that are shaping its future.

With regulations evolving rapidly—from California’s MCRSA laws to upcoming FDA and USDA requirements—achieving cGMP compliance has become absolutely essential. Therefore, it is no longer optional; in fact, it is the critical foundation for ensuring product safety, consistency, and market readiness.

Build for Compliance. Design for Growth.

PortaFab is already an established leader in USP <797> and USP <800> compliant compounding cleanrooms. Consequently, we bring unmatched, directly applicable experience to medical cannabis production and processing. Since these very standards are expected to guide future cannabis compounding operations, partnering with PortaFab positions you ahead of the curve, ready to meet escalating regulatory demands with confidence.

Our modular systems are specifically engineered to deliver precision, reliability, and scalability. As a result, we can provide everything from basic temperature and humidity-controlled spaces to fully validated, pharmaceutical-grade cGMP cleanroom environments.

Why Choose PortaFab for Cannabis Cleanrooms?

Transitioning to fully compliant production is a strategic step, and with PortaFab’s flexible, modular cleanroom systems, the process is seamless.

Proven Compliance Heritage: We offer decades of direct expertise in cGMP, FDA, and USP cleanroom design, ensuring your facility is built on a foundation of trust.

Effortlessly Scalable Design: As your operation expands, you can quickly add or reconfigure spaces without major downtime.

Precision Environmental Control: Critically, our systems maintain tight control of air quality, temperature, and humidity to protect your product integrity.

Future-Ready Compliance: Our systems are built to meet evolving cannabis regulations, helping you pass inspections and enter new markets.

Cost-Effective Construction: Modular installation significantly reduces build time and overall project costs compared to traditional construction.

Engineered for Flexibility and Uncompromising Performance

Unlike rigid traditional construction, PortaFab’s interchangeable modular wall and ceiling systems offer unparalleled design flexibility. You can actively combine a wide range of panels, doors, windows, and accessories to create a layout that perfectly matches your unique operational workflow.

This strategic adaptability not only ensures long-term value but also allows you to reconfigure spaces easily as production standards evolve. Ultimately, this helps your business remain compliant, efficient, and confidently future-ready.

Partner with PortaFab to Future-Proof Your Facility

From cultivation and extraction to processing and packaging, PortaFab delivers cleanroom solutions that actively ensure compliance, consistency, and operational excellence at every stage. Don’t just adapt to the future—define it.

📞 Contact us today to discuss your facility needs and discover how PortaFab can help you achieve cGMP-compliant, high-performance environments that grow with your business. qc@perotech.com